Slab on ground foundations

Using sturdy and waterproof FINNFOAM can significantly improve the performance of a slab-on-ground foundation and increase its resilience. The resilience of a structure is one of the most important guarantees for its functionality and durability. If the thermal insulation is installed under the slab, the structure will be significantly more resilient towards water damage, for example. With today’s increasingly thick base floor insulations, it is very important to ensure that the strength of the insulation is also increased in proportion. If this is neglected, the compression of the insulation will increase, leading to expensive repairs, as baseboards have to be dropped down and torn waterproofing in wet rooms will require mending. More information about these issues can be found below!

KEEP YOUR SLABS DRY!

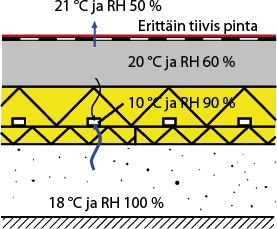

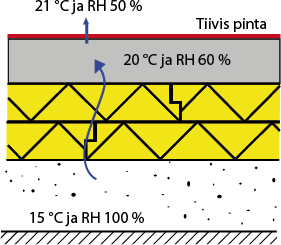

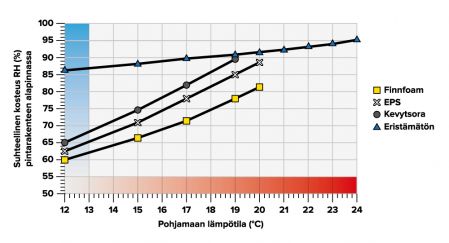

The relative humidity of the ground under the base floor insulation is always 95–100%. Thus, it is important to ensure that your thermal insulation has a high enough water vapor resistance and that it cannot become waterlogged. Waterlogged insulation will no longer function as designed, and it will also leave the poured floor moist, which may lead to indoor air issues. FINNFOAM is waterproof!

With proper thermal insulation, you can also avoid overheating the subgrade in small houses, where the construction span of the building is quite small. The risk of overheating will always be higher when underfloor heating is used. If the construction span of a building is increased, the amount of thermal insulation required will also grow. As FINNFOAM does not allow water vapor through, it provides time for the concrete slab to dry on the inside. Thus, the moisture content of the concrete slab is lower and the moisture performance of the structure is improved.

During a hot and humid summer, water vapor flows down toward the ground from the inside. This is why you should never place separate plastic vapor barriers between any of the slab-on-ground structures, as they reduce the moisture performance of the structure! To curb the flow of water vapor, thermal insulation should be highly resistant to water vapor, which is true for FINNFOAM. (Source: VTT and TTY).

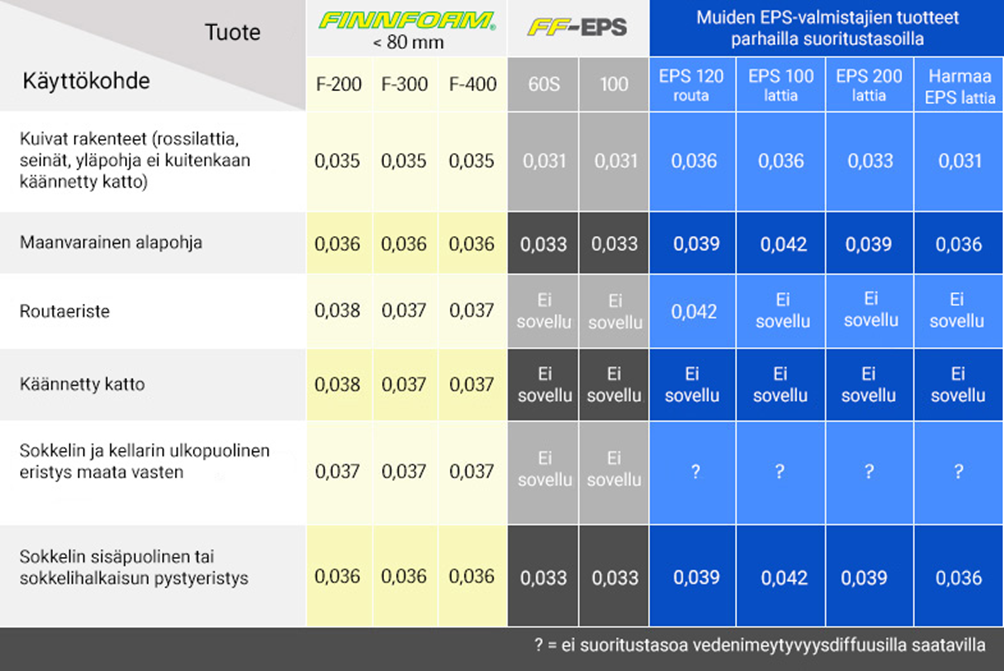

ACTUAL THERMAL CONDUCTIVITY IS DECLARED USING LAMBDA U UNDER RIL 225-2023

The declared thermal conductivity of thermal insulation and frost insulation materials (expressed as λDeclared) represents the optimal thermal conductivity of the product when dry. However, the design and dimensioning of base floor and frost insulation should always be carried out using the actual thermal conductivity of the products, i.e., lambda U (λU), which takes into account the detrimental impact of moisture on the thermal insulation capacity of an insulation product. To allow us to calculate λU values for insulation products used in the ground, we must know the water absorption of the product used when immersed, through diffusion, and after freeze-thaw resistance testing.

Below you will find lambda U values calculated for FINNFOAM and FF-EPS insulation products in ground-based applications, i.e., slab-on-ground foundations, vertical insulation on the inside or outside of foundations, and frost insulation. In addition, we have also listed actual lambda U values of other EPS insulation products used in similar applications for comparison.

The Lambda U values in the enclosed table have been calculated using the following formula based on the EN 10456 standard and the RIL 225 instructions:

λU = λD x FT x FM x Fa

λD = Declared thermal conductivity (Lambda), FT = Temperature conversion factor, FM = Moisture conversion factor, Fa = Aging conversion factor

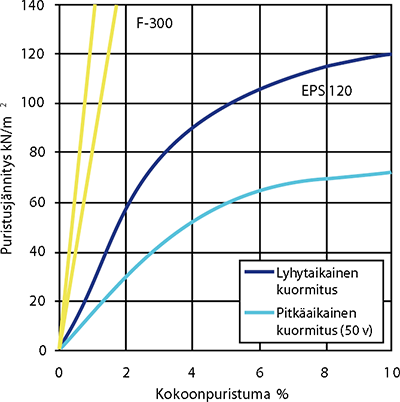

DO NOT ALLOW THE SLAB TO SUBSIDE

When the thickness of thermal insulation increases, the insulation must also be made stronger. Neglecting this will lead to higher subsidence. This is particularly emphasized today with growing base floor insulation thicknesses, as we are increasingly moving toward zero-energy houses. The following can be used as a rough guide for the sufficient strength class of floor insulation in residential buildings: With 100 mm of thermal insulation, the sufficient short-term compressive strength is 100 kPa, 200 mm insulation = 200 kPa, 300 mm = 300 kPa, etc.

The sturdy FINNFOAM has a very low subsidence, as it reaches its maximum strength (short-term compressive strength) at approximately 2% of compression, and thus its long-term compressive strength is also very high. FINNFOAM is also sturdy enough to be used for constructing solid thermal insulations under fireplaces and load-bearing partition walls. When used in floors, FINNFOAM insulation products are also highly resistant to point loads during construction without crumbling.

The long-term subsidence of FINNFOAM (F-300, 32 kg/m³) is less than one tenth of the subsidence of EPS materials commonly used in floors (EPS 120 20 kg/m³ or EPS 100 18 kg/m³).

COST-EFFECTIVE PANEL SIZE

FINNFOAM insulation panels are highly resistant to the strains resulting from casting while constructing a split footing. As the sturdy FINNFOAM can be used to both insulate the footing and to construct molds for casting, the work is guaranteed to be efficient. The smooth surface of FINNFOAM allows it to be removed intact after casting as it does not stick to the concrete. On the other hand, if you want the insulation to adhere to the concrete, you should scratch or flute the surface of the FINNFOAM panels slightly. FINNFOAM insulation can be installed afterward on top of the footing using renovation mortar, for example. You can apply a thin coat of render on top of the FINNFOAM panels in accordance with the instructions provided by Fesco, for example.

The standard FINNFOAM panels are quite large at 2 500 x 600 mm, or 1.5 m2. The panels are still suitably sized and light enough for one person to handle, which means that their installation is cost-effective.

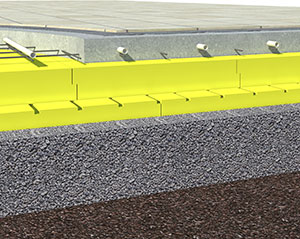

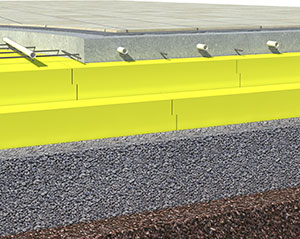

VENTILATED SLAB-ON-GROUND FLOORS

FINNFOAM can also be used for constructing ventilated slab-on-ground floors, where a compact network of ventilation channels is created between two layers of insulation. Even limited ventilation is enough to eliminate the water vapor load coming from the ground through the lower layer of FINNFOAM. The ventilation has no effect on the thermal insulation capacity of the structure. The ventilation channels must be produced in an uninterrupted manner.

Natural convection will generate a small amount of ventilation, which means that when ventilation is not needed in the summertime, its amount is reduced. Most of the radon moving up from the ground will also be removed through the same ventilation channels.

A ventilated slab-on-ground floor structure constructed with FINNFOAM will also work in larger buildings where the ground temperature is higher in the middle of the building. In addition, the surface material of the slab may be highly vapor proof. The structure will also reduce the radon risk.